Piping for all media in any dimension.

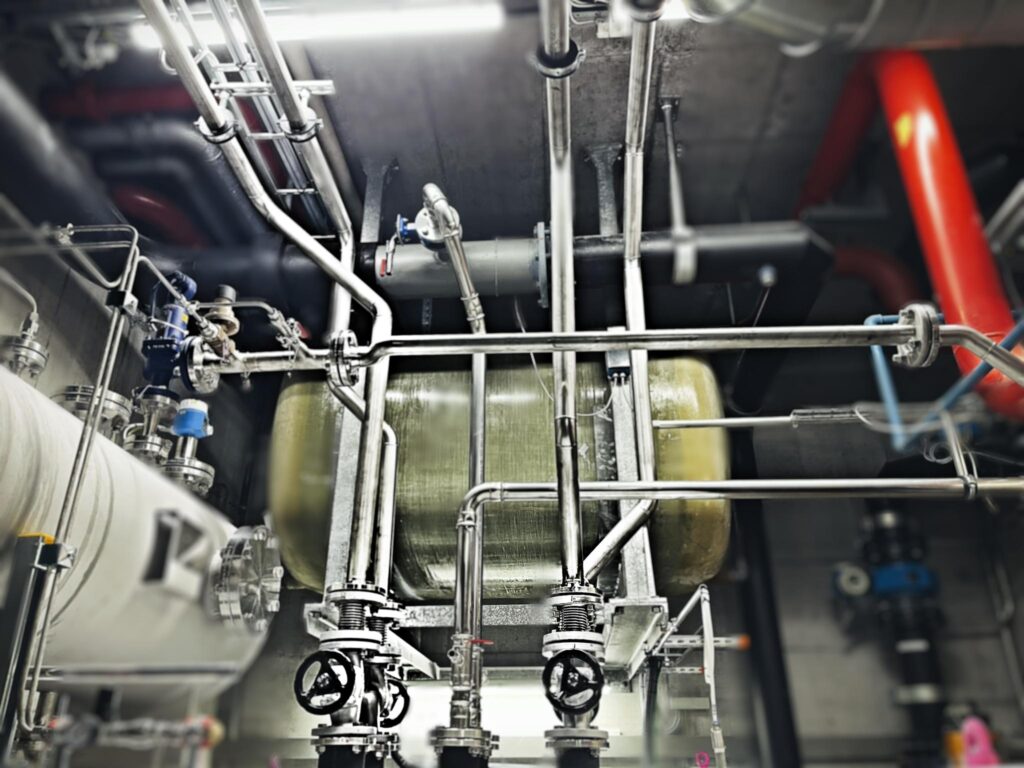

We manufacture pipes for all requirements in the food, pharmaceutical, and beverage industries. K‑Tech meets the highest standards of welding quality. To this end, we use all known welding processes, from TIG to orbital welding.

Documenting the welding seams according to an isometry, as well as Ferit measurements are standard for us. Our internal welding supervisor (IWS= International Welding Specialist) with a federal certificate of proficiency ensures consistent quality tailored to the customer.

Pipework construction can be individually adapted to the customer. From 3D pipe planning to prefabrication and then to assembly and commissioning, with us everything is under one roof. Since we are constantly adapting our internal processes to the market, you as a customer can rely on the latest technologies through K‑Tech GmbH.

If you are looking for a pipeline builder who can implement your wishes on time and at fair conditions, you have the right partner at your side with K‑Tech GmbH.

Examples

We like to find solutions that are optimised for the customer in terms of price and performance. At the same time, we always keep an eye on certifications and safety. We know the different loads that pipework has to withstand and calculate each pipe based on the customer’s specifications. All welding work is certified in accordance with standard regulations, and our welders also have a valid certificate authorising them to carry out welding work.